Lube oil filtration for locomotives

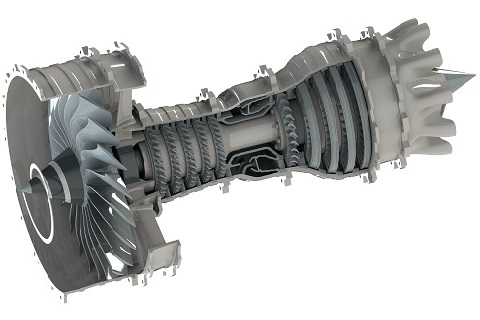

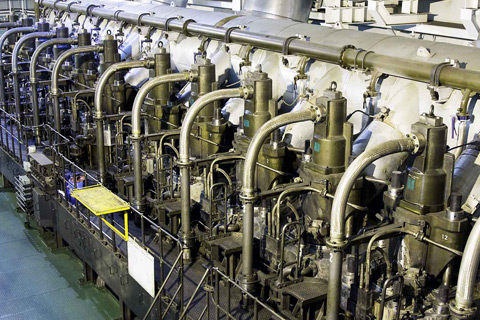

In locomotives diesel engines, soot particles are created through the incomplete combustion of fuel. Most of these soot particles are either combusted later or they travel through the exhaust system into the atmosphere. Some particles will end up in the lubricating oil by means of piston blow-by. Soot particles are 98% carbon and are quite hard and abrasive. When they end up in the oil they can clump together and act as abrasives to the rotating components of the engine. Additives in modern lubricants keep the soot particles in suspension and prevent them from clumping together to some extent, but these can soon be overwhelmed once soot concentration reaches a certain level. A high concentration of soot can cause filter-blocking, excessive bearing and piston-ring wear and eventually costly rebuilds.

Over time there will also be a buildup of small metallic particles. This is due to the friction between rotating and sliding components during normal engine operation. It is important to filter and remove these metallic particles from the oil.

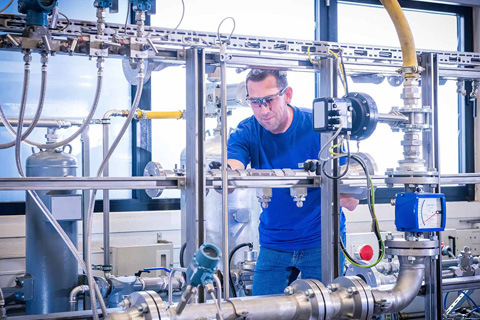

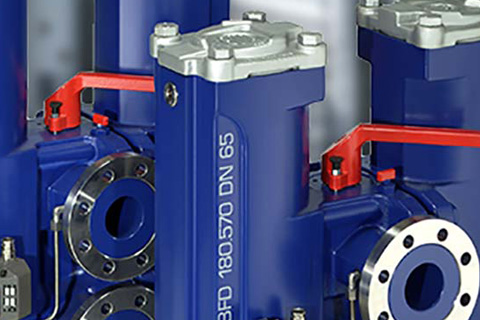

It is absolutely vital that a diesel engine has an effective lube oil filtration system. The BOLLFILTER Automatic Type 6.48 takes over this task perfectly.

PROTaC Basic – suitable for high oil pressure engines

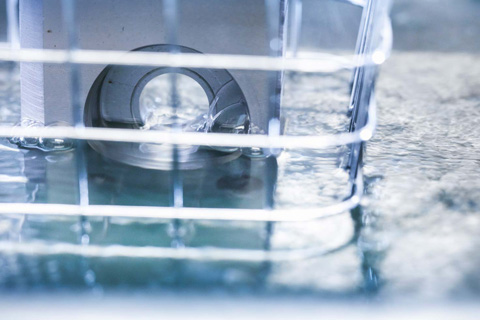

The PROTaC Basic consists of a BOLLFILTER Automatic in the main oil flow and an oil centrifuge installed in a bypass line, ideally directly after the engine oil pump. The centrifuge takes a small amount of oil from the main flow, cleans it and feeds it back to the oil sump. The BOLLFILTER Automatic filters the oil to be fed to the engine and a small backflushed amount is returned to the oil sump.

This configuration has the advantage of being simple to install and not requiring any external power source. Both the BOLLFILTER Automatic and oil centrifuge function purely on oil pressure.

PROTaC Premium - suitable for all engines

Some engines have inherently low oil pressure at the filter inlet. Other engines may also spend large amounts of time idling, generating lower oil pressure in doing so. This pressure may be insufficient to properly drive the centrifuge and backflush the filter.

For these applications we have developed PROTaC Premium. This system consists of a BOLLFILTER Automatic in the main oil flow with an electric pump in the backflush line followed by an oil centrifuge. The pump sucks the oil through the backflush line, effectively flushing the candles and then pumps the oil at high pressure to the centrifuge.

Your Benefits:

- Self cleaning automatic filter

- Filter candle elements are continuously backflushed, eliminating frequent filter element changes

- Filtration grade remains constant

- Lower pressure loss = reduced fuel consumption

- Self cleaning mechanism powered purely by oil pressure (PROTaC Basic)

- Much lighter and more compact than paper filter housing

ReferencesHavelländische Eisenbahn »Havelländische Eisenbahn trusts BOLLFILTER for the automatic oil fitration in replacement of the paper filters.

DownloadsBOLLFILTER Automatic Type 6.46 with centrifuge

BOLLFILTER Automatic Type 6.48

BOLL & KIRCH

BOLL & KIRCH BOLL & KIRCH

BOLL & KIRCH BOLL & KIRCH

BOLL & KIRCH

shutterstock

shutterstock Adobe Stock

Adobe Stock iStock

iStock shutterstock

shutterstock shutterstock

shutterstock shutterstock

shutterstock shutterstock

shutterstock Getty Images

Getty Images Fotolia

Fotolia

shutterstock

shutterstock Fotolia

Fotolia

shutterstock

shutterstock Getty Images

Getty Images

shutterstock

shutterstock

Getty Images

Getty Images Getty Images

Getty Images Fotolia

Fotolia shutterstock

shutterstock shutterstock

shutterstock shutterstock

shutterstock BOLL & KIRCH

BOLL & KIRCH BOLL & KIRCH

BOLL & KIRCH BOLL & KIRCH

BOLL & KIRCH