Bollfilter

- Filters

- Membranes

- Applications

- Renewable Energy

- Protection of Water Systems

- Water filtration in irrigation

- Exhaust Gas Recirculation (EGR)

- Ballast Water Management Systems

- Exhaust Gas Cleaning Systems

- Offshore Water Injection Systems (FPSO)

- Floating Storage and Regasification Units (FSRU)

- UV Systems in Wellboats

- Sewage Treatment Plants

- Potable Water Plants

- Steam Turbines

- Snow Machines

- Desalination Process

- Heating Ventilation Air-Conditioning Systems HVAC

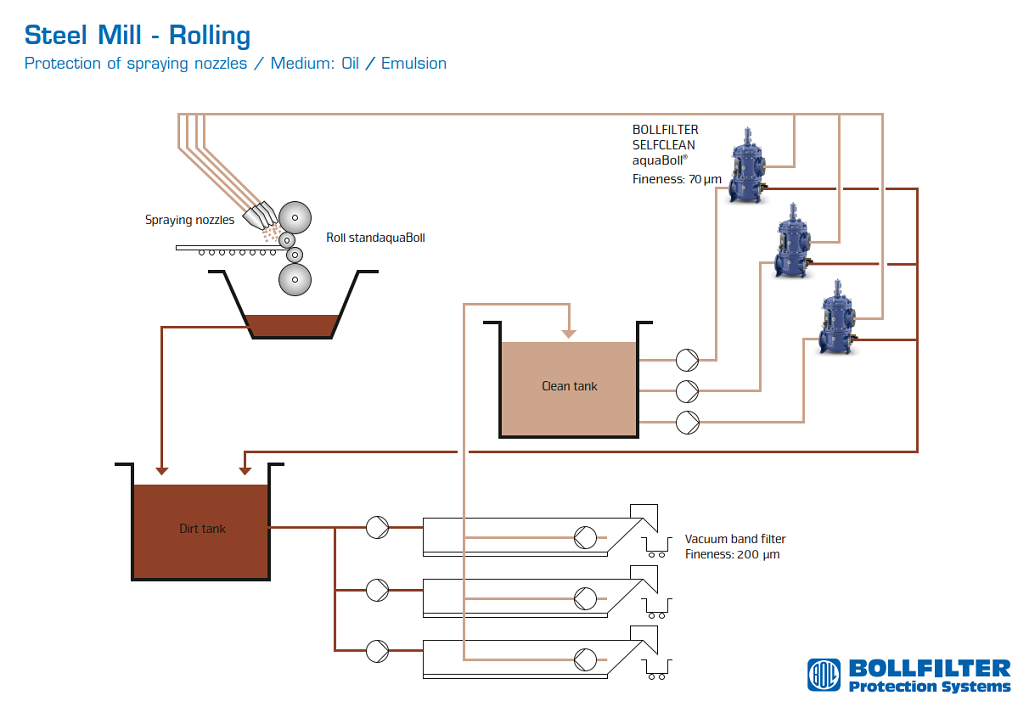

- Steel works

- Pulp and Paper

- Protection of Engines

- Protection of Compressors and Turbines

- Protection of Fleets

- Protection of Machining & Cleaning Systems

- Spare Parts

- Service

- Company

- Contact

- Information